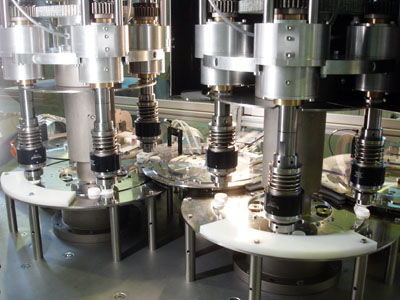

Continuous motion machines for screwing assembly of multiple parts closures

|

CVR series are machines for caps assembly by screwing (threading) components. High production rotary machines for caps without orientation among its components or intermittent machines (indexed) for smaller productions. Each one designed according to the necessities of the product and the technical requirements of each application. For cases in which high production where the parts to be assembled require a previous orientation to each other and it is not possible to direct them into the feeders, we propose the CVS assembler, which incorporates servo motors in each threaded column and angle measurement system on parts by machine vision. The size and design of the assembly machine is adapted to the necessity of the project: 4, 8, 12, 16 or 24 threaded columns for speeds of 6.000, 12.000, 18.000, 24.000 or more pieces per hour respectively. MAIN FEATURES

|

|