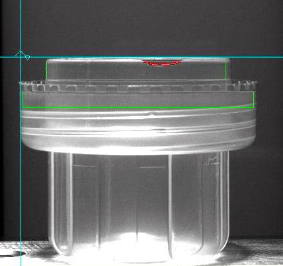

Artificial vision caps verification

|

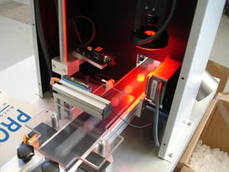

VA Series. Complete equipment of artificial vision caps verification quality, removal of defective parts and correct classification

• Axial or radial burrs • Lack of material • High injection point • Straight micro-pore • Discoloration or stains on the surface • Other functional defects: thread, shutter, misplaced wad, etc.

|

|