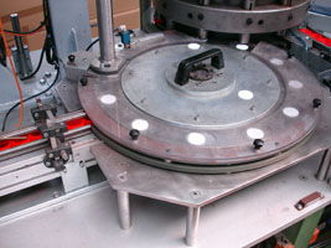

Pre-cut wads insertion machine

|

CVJ and CIJ series are automatic insertion machines for round or pre-cut wads from a vertically cartridge or bulk inside plastic or aluminum caps. Depending on the speed required in the process, there are available two different types of machine:

The configuration and size of each equipment is determined by the required production and the characteristics of the handled wad. For high production threading machines are suitable, for applications with delicate aluminum foil wads intermittent machines (indexed), and for reduced production linear machines.

The equipment supports multiple different types of caps: round, square, tapered, hinged, etc. Depending on which, the equipment will incorporate one or another type of cap feeder and other peripherals. Admissible geometry of wad cut and inserted can be diverse: round, disk (donut) or with side flaps. And the material of manufacture can be cardboard, PE, foam, polexam, etc. MAIN FEATURES

|

|