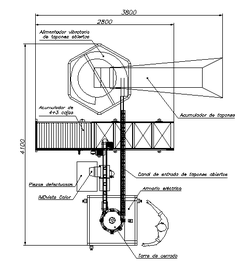

Flip-top closing machine

|

CVB series are machines for closed off mold of flip-top caps. Given the high importance of the hinge for a correct feed in the closing machine, normally this is in line with the injection to not store the open caps deforming the hinge and disabling its further automation. Customized configuration depending of each type of hinged cap: continuous motion closing machine for standard caps, rotary indexed machine for very special designed caps or lineal indexed machine for small production The equipment supports multiple different types of caps: cosmetic parts, caps for packaging oil, detergent, etc. In all cases, open injected parts’ feeding is performed by a vibratory feeder. It is always advisable to incorporate output conveyors injection and accumulation elevators between the injector and the closed line. The size and design of the machine is adapted to the necessity of the project: 8, 12, 16 closed columns for speeds up to 10.000, 15.000, 20.000 or more pieces per hour respectively. MAIN FEATURES

|

|